If you’re looking forward to invest 1000+ usd (something cheaper is a matter of a pure luck) in a inflatable SUP, you’ll have to make a little research as to the matter. Nevertheless, most brands give so little details aside from a bunch of ‘our boards are fantastic’ claims in the promotional material, and some exploded-view diagram that looks cool and shows plenty of layers.

That is because they don’t really know about what happens inside their inflatable boards! The inflatable manufacturing process is left to the factory, who make SUP boards as OEM production for dozens of brands. And if you own a brand your involvement generally is just choosing the colors, shapes and fittings. If you don’t believe you can go to the website alibaba.com and search for “inflatable sup boards” term.

So, here we’ll explain every aspect of inflatable sup paddleboard production, and what to avoid.

Inflatable SUP Manufacturing in-depth understanding

All inflatable SUP boards from the different brands are coming from just half a dozen of main factories in China and South Korea. But every factory use vastly differing techniques and standards. Some factories are manufacturing for few dozens of different brands. Factories are inclined to follow its own standards and technique, so essentially all the boards coming out of one factory look quite similar.

As a matter of fact, inflatable SUP board construction is often utterly low-tech. Panels are cut out manually and glued manually, just on the factory workshop floor or on simple workbenches. Also, it’s far away from being a sterile process, and there is a lot of opportunities for dust to get into the seams, producing leak spots. That is why cheap quality inflatables are not a wise investing.

The quality range of the various factories is enormous, and the first-ranking plants are in technical terms much ahead of the competitors. Working to higher standards, they can produce inflatable boards which are able to bear much higher pressure and have much better shapes and lines.

SUP boards dropstitch material

This is inside every inflatable SUP board, and prevents it becoming a ‘sausage’ when the board is pumped up.

The iSUP boards by Mistral, Naish, C4, Starboard, Red Paddle Co, Fanatic, RRD, Hobie, BIC (yes, that one who makes pens also) and all the other brands all have dropstitch in the heart of their boards. However, many different kinds are used.

Dropstitch is essential for all inflatable SUP boards. It’s a manufacturing process that makes two layers of cloth (board’s surface) “tied together” by tens of thousands of very thin polyester threads. Thin to the extent that when the iSUP board is deflated, it can collapse almost completely flat, being able then to be rolled up and packed away. Dropstitch mostly is produced in Korea and the manufacturing process is very slow. Special machines churn it out at a pace just a few inches per minute. Therefore it’s quite a costly material.

Dropstitch is produced in a variety of different thickness, stitch densities, and patterns (whether the stitches run in diagonal lines; or whether they are in parallel lines — “linear dropstitch”).

Evidently, a greater density using a non-linear pattern will make a much tougher construction. Linear dropstitch is much less expensive, but it’s easy to get torn and produces natural ‘fault lines’ running along the surface.

Better quality inflatable SUP boards use the highest-density diagonal dropstitch

The most frequent thicknesses of dropstitch is in range between 100 mm and 150 mm. The thicker threads give more rigidity when the iSUP board is inflated up to appropriate pressure.

Rails

How the sides of an iSUP board are made tells a lot about how it will perform in water.

The dropstitch material provides the top and bottom of the board. But it is also essential how to finish the sides (so called ‘rails’). There are three different techniques in operation to create the rails:

- The Woosung Rail: a side panel is taped on. These boards are identifiable by the line of tape along the top and bottom of the rail. Far and away the weakest way to make a rail.

- The Leewards Rail: alike the Woosung rail but with additional layer added over the top, to make the effect of one big rail panel. Better than the Woosung rail, but nevertheless just two layers on the rails.

- The Infla Rail: the top and bottom layers are got together to ajoin, and then taped. Another exterior laminate is then applied to repeat the whole process. So the rail is 4 layers thick. Far and away the most efficient rail making technique.

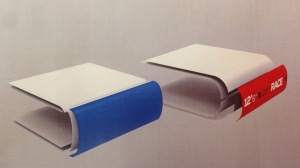

On the left (blue) is the Leewards rail. On the right (Red) is the Infla rail.

The core difference between the first two approaches and the third one is that the Infla technique only makes one seam instead of two. It’s an a lot more complicated and labor-intensive way of making a rail, but the outcome is much better. The rails are far less likely to leak over time.

SUP boards thickness

The thickness of an iSUP board plays a great part in determining its performance and stability. Excessive thickness is no good!

Creating a board thicker will make it more rigid but it will also affect the performance on water. The board suffers greatly in terms of manoeuvrability and stability. It also has a lot more windage if the nose rocker is over-generous, as on the cheap inflatable boards.

The shape and thickness should be appropriate and suit each other as well as suit the board’s role.

100 mm thickness is ideal for SUP boards with a surf orientation.

The thinner rails contribute to better control on the wave. Such boards don’t offer the best rigidity however.

120 mm thickness is the perfect match of rigidity and control for “all round” boards.

120 mm board allows the SUPer to keep a low center of gravity without compromising of stiffness.

150 mm thickness is ideal for non surfing SUP boards where directional stability is exceptional.

It gives good stiffness and means the board has enough volume to carry a heap of equipment or in some cases it makes the board float high to decrease drag when racing.

150 mm is not suitable for general recreational aims however, as it suffers a lot more windage, needs an awful lot more pumping-up efforts, and much lowers “all-round” boards performance. You could just have a look at what happens in solid boards. You’ll never see an “all-round” solid board which is 6″ thick — you don’t need it for inflatables too.

iSUP Boards Rocker

There are few different ways employed to put a rocker curve into an inflatable SUP board. But most have a quite harmful effect on the board’s behavior.

Shaping an appropriate rocker profile (the curve line from tail to nose, which is seeing from the side) into an inflatable SUP board is an intricate process.

Basically, there are three techniques utilized to create rocker line in inflatable SUP boards.

The first, most crude and, frankly speaking, rarely used, is just joining sections of dropstitch with a bevel. It allows to create a change in angle. As on the picture below.

The ordinary low-tech method employed nowadays is cutting the top of the dropstitch threads at a shorter length to the bottom, in such a way that when they are ajoined it creates a natural turn-up when under pressure.

The most advanced method employs a Progressive Pressure Laminating Process. The SUP board is laid on a special surface. As the upper layer is laminated on to the SUP board, then the high pressure rollers are pushed over the board fixing the rocker curve. It is then left to set, letting them to make a progressive rocker line profile that is perfectly matched to the SUP boards shape and the inflatable structure. After that they apply further layers of laminate tape to lock the established rocker curve. This is a lot more technically sophisticated process, but the outcome is rewarding and gives a genuine paddleboarding experience.

The first two technologies result in SUP boards which are flat in their middle part, and then turn up rapidly at the nose section, and occasionally at the tail as well. The performance of such SUP boards is significantly worse. They suffer stronger windage and those towering noses literally get blown away.

Contrast the rocker line on the boards in these two photos.

Any inflatable SUP board with an abruptly-upturned nose part at once tells you that it was produced on one of the factories making low-pressure inflatables.

iSUP board weight

Light weight inflatable SUP boards are a conceptual mistake.

If we talk about solid boards, a lighter board has usually better properties. It accelerates faster and is more responsive. The weight was saved by employing carbon, better glass or epoxy. At the same time it usually means more money to be spent for buying such a board.

Nevertheless, with inflatables, weight cannot be considered in the same way. The reason is that there is one way to make an inflatable paddleboard lighter. You have to compromise with having a thinner skin, or less dropstitch material.

So, a light-weight inflatable SUP board will always be less rigid and more inclined to damage.

PVC doesn’t have lighter-but-better grades. And using dropstitch with a less number of threads, inevitably, brings about a lower quality SUP board. And performance gains from the weight saving are totally offset by the loss of stiffness. Light but floppy board loses much more power of a paddle stroke than any benefits from being a lighter.

SUP Board Stiffness

The stiffer the paddleboard, the better its performance. There are four ways to create stiffness in an inflatable paddleboard:

Air pressure.

The more air inside, the more stiff the paddleboard will be. The difference between a board inflated to 10psi and one to 20psi is striking. But you have to know that the benefits become vanishingly small once you pump up above 25psi. You shouldn’t buy an inflatable SUP board that can’t be inflated up to at least 20psi.

Thickness.

A 120mm thick board is almost 40% more rigid than a 100mm board other conditions being equal. However, a thicker SUP board needs more air to pump in, sits higher on the water surface and is less proper for surfing.

Width.

It is one of the determinants of the stiffness. But an excessive width brings about a good deal more drag and is harder to paddle, so the width still needs to be appropriate for the board’s use.

You may also be interested in reading: